High Quality Transfers Explained in Under 3 Minutes: DTF vs. Sublimation vs. HTV

Share

Have you ever stood in front of your heat press, holding three different transfer types, wondering which one will give you that crisp, professional look your customers expect? You're not alone! With DTF, sublimation, and HTV all promising amazing results, choosing the right transfer method can feel overwhelming.

Don't worry: we're breaking down everything you need to know about these three powerhouse transfer methods in under 3 minutes. By the end of this guide, you'll know exactly which method to reach for based on your project, budget, and quality goals.

What Exactly Are These Transfer Methods?

Let's start with the basics. Each of these methods gets your design from concept to fabric, but they work in completely different ways.

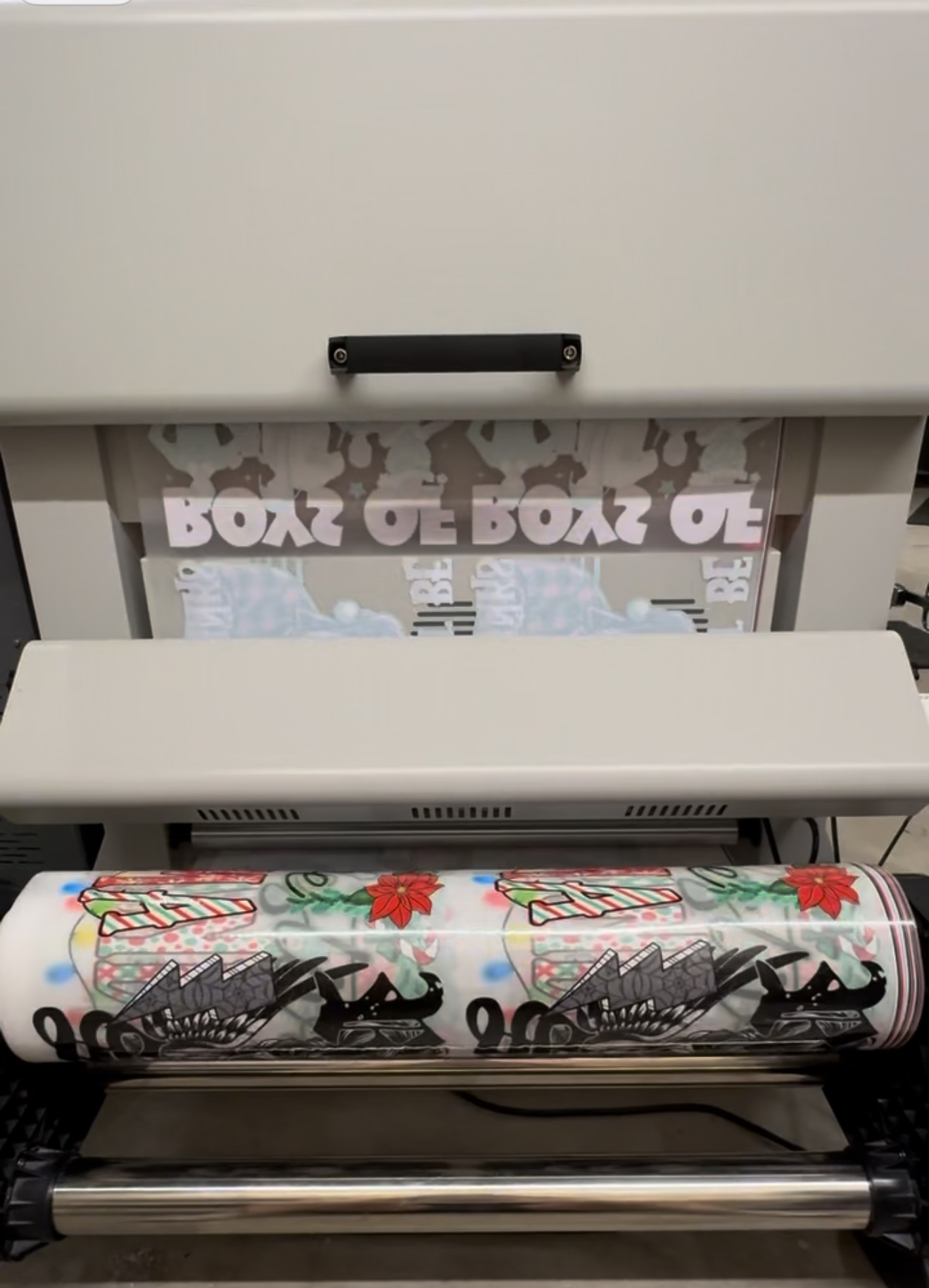

DTF (Direct-to-Film) prints your full-color design onto a special film, applies adhesive powder, then heat presses it onto virtually any fabric. Think of it as a high-tech sticker that becomes part of your garment.

Sublimation uses special inks that turn from solid to gas when heated, permanently bonding with polyester fibers. The ink literally becomes part of the fabric: no texture, no peeling.

HTV (Heat Transfer Vinyl) involves cutting pre-colored vinyl into your design shape and heat pressing it onto fabric. It creates that classic raised, textured finish you see on team jerseys and custom tees.

The Quick-Start Comparison Guide

Here's your at-a-glance breakdown of what each method brings to the table:

| Feature | DTF | Sublimation | HTV |

|---|---|---|---|

| Works Best On | Any fabric type, any color | 100% polyester or light colors only | Cotton and cotton blends |

| Print Quality | Photorealistic, full-color detail | Ultra-vibrant, professional grade | Limited colors, clean lines |

| Texture Feel | Soft, flexible finish | Zero texture: part of fabric | Raised, vinyl texture |

| Durability | Excellent with proper care | Permanent: won't fade or crack | Good, but may crack over time |

| Startup Cost | Higher equipment investment | Higher equipment investment | Most budget-friendly |

| Best Project Type | Detailed artwork, large orders | Professional merchandise, sports gear | Simple designs, small batches |

DTF: The Versatile Powerhouse

DTF has become the go-to choice for many small businesses, and for good reason. This method works on cotton, polyester, blends, dark fabrics, basically everything in your inventory.

When DTF Shines:

- You need photo-realistic prints with tons of detail

- Working with dark fabrics (DTF includes a white base layer)

- Producing larger quantities efficiently

- Want flexibility across different fabric types

The Reality Check: DTF requires a significant upfront investment in equipment and supplies. The learning curve isn't steep, but you'll need to master temperature, pressure, and timing for consistent results.

Sublimation: The Professional Standard

Sublimation creates the most durable, professional-looking transfers you can achieve. The ink becomes part of the fabric itself, which means no cracking, peeling, or fading: even after hundreds of washes.

When Sublimation Wins:

- Creating premium merchandise or uniforms

- Working with 100% polyester garments

- Need the most durable finish possible

- Printing on mugs, phone cases, or other polyester-coated items

The Limitation: Sublimation only works on polyester or polyester-coated surfaces, and shows best on white or very light-colored items. Dark fabrics? Not happening with sublimation.

HTV: The DIY Favorite

Heat Transfer Vinyl remains popular for good reason: it's accessible, affordable, and perfect for certain types of projects. You can start with just a cutting machine and heat press.

When HTV Makes Sense:

- Simple text or logo designs

- Small batch or one-off projects

- Working within a tight budget

- Need quick turnaround times

Keep in Mind: HTV works best for simpler designs. Complex, multi-color artwork becomes expensive and time-consuming to weed and apply.

Quality Factors That Actually Matter

Not all transfers are created equal, regardless of method. Here's what separates professional results from amateur-looking prints:

Color Accuracy: DTF and sublimation excel at reproducing exact colors, while HTV limits you to available vinyl colors.

Washability: Sublimation wins hands-down for wash durability. DTF follows close behind with proper curing. HTV can crack or peel if not applied correctly.

Hand Feel: Sublimation feels like nothing: because it IS the fabric. DTF creates a soft, flexible layer. HTV always has that vinyl texture.

Fine Detail: DTF handles intricate details beautifully. Sublimation captures fine text and gradients perfectly. HTV struggles with tiny details due to weeding limitations.

Making the Right Choice for Your Business

Your decision should align with your business model, customer expectations, and budget reality.

Choose DTF if:

- You serve diverse customers with various fabric preferences

- Quality and versatility matter more than equipment cost

- You're scaling up production volume

- Your designs include lots of colors and details

Choose Sublimation if:

- You focus on premium, professional-grade products

- Your niche involves polyester garments or promotional items

- Durability is your customers' top priority

- You're willing to work within fabric limitations for superior results

Choose HTV if:

- You're starting out or working with limited budgets

- Your designs are typically simple text or shapes

- You enjoy the hands-on cutting and weeding process

- Quick, small-batch projects are your bread and butter

Pro Tips for Better Results

Regardless of which method you choose, these insider tips will elevate your transfer quality:

Temperature and Time: Invest in a reliable heat press with accurate temperature control. Those cheap presses with inconsistent heat will ruin even the best transfers.

Pressure Matters: Too little pressure and your transfers won't adhere properly. Too much can cause cracking or color bleeding.

Curing is Critical: DTF transfers need proper curing time and temperature for maximum durability. Don't rush this step.

Test First: Always test new transfer types, fabrics, or settings on sample pieces before running full orders.

The Bottom Line

There's no single "best" transfer method: only the best method for your specific situation. DTF offers incredible versatility, sublimation delivers unmatched durability, and HTV provides accessible entry into custom printing.

The most successful small businesses often use multiple methods depending on the project. A DTF setup for detailed designs and diverse fabrics, plus HTV for quick simple projects, gives you flexibility to serve more customers effectively.

Start with the method that best matches your current needs and budget, then expand your capabilities as your business grows. The transfer world is constantly evolving, and staying adaptable will keep you ahead of the competition.

Ready to take your transfer game to the next level? The right choice depends on your specific goals, but armed with this knowledge, you can confidently choose the method that'll deliver the professional results your customers expect.